The group of companies includes the production of cold stamping, the production of stamps and molds, and supplies consumers with high-quality parts to ensure the main conveyor and other continuous production processes.

Serial production of stamped products, manufacturing of tooling and molds, as well as the services of a measuring laboratory for the automotive, construction and chemical industries

The group of companies conducts projects for the full life cycle from receiving a request > Product Development > Process Design and Tooling > Tooling Manufacturing > Preparing for Production >to Serial Stamping and Delivery

The group of companies has the financial resources for stable and guaranteed serial deliveries and preparation of production, this is confirmed by the rank of Sberbank PJSC - Rank AA “Very High Creditworthiness” DUNS Index - Rank B2 Dun & Bradstreet Rating Good Creditworthiness

The production and project management of the group of companies meets the high requirements of the automotive industry. This is confirmed by certificates.

We are ready to adapt the production to the requirements of the customer, if necessary, prepare and pass an audit of the customer.

Two lines of presses produce up to 120 work cycles per minute and are ideal for the manufacture of fittings, angles, needle plates. In normal operation, one press produces up to 50,000 parts per day.

More than 20 traditional stamping presses are used to make parts of more complex designs. Professional press operators provide quality parts and high productivity.

Own stamp production ensures repair and low maintenance.

The production team is prepared for the preparation of production. This reduces time and indirect costs. Internal production logistics, quality control of stamped parts of equipment after each technological operation eliminate interference in the production process.

CNC milling machines - 4 units.

Erosion machines - 2 units.

Grinding machines - 3 units.

The production site for the heat treatment of metals and the production site for the assembly of die tooling. Measuring laboratory and testing equipment.

Own stamp production ensures repair and low maintenance.

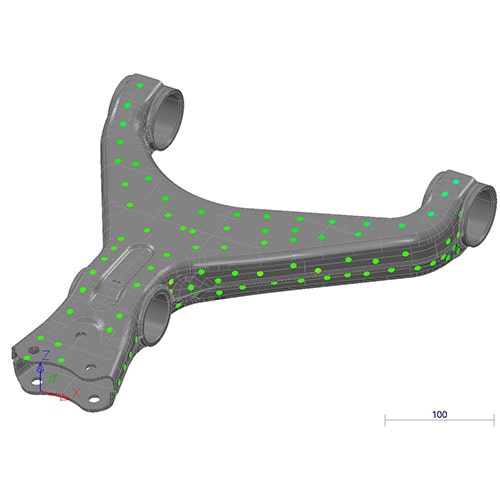

On average, in the manufacture of each die tooling, 1000 measurements of geometric parameters, hardness and roughness are performed.

High-quality materials from

Böhler and SCHMOLZ+BICKENBACHare used for the manufacture of die tools and control gauges.

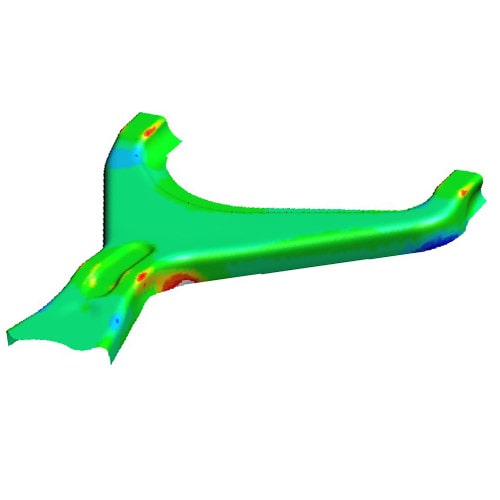

3D measurements

Reverse Engineering

Setting, verification and certification of calibers, fixtures and accessories

Hardness, roughness measurements, macrographic studies of welded joints

High-precision measurements, analysis and consultation from specialists in this

Approval of documentation / selection of material for production

Design and improvement of technological processes

Prototyping (if required)

Achieving process targets

Production preparation includes monitoring the schedule and coordination of the process participants. A report on the preparation of production is sent to the customer upon his request.

Usually the production process is checked by the consumer before the start of supply. For our part, to ensure quality while increasing production volumes, Firewall procedures are used.

Preparation for the production of each part or several parts is considered as a project. For each project, we calculate the costing, financial model and coordinate the costs with the consumer. Thus, together with the consumer, we are looking for ways to reduce the cost at the beginning of the project.

Approval of costing Providing financial statements during delivery

The cost of pre-production is included in the cost of the part

Fewer contracts fast localization and low cost of parts